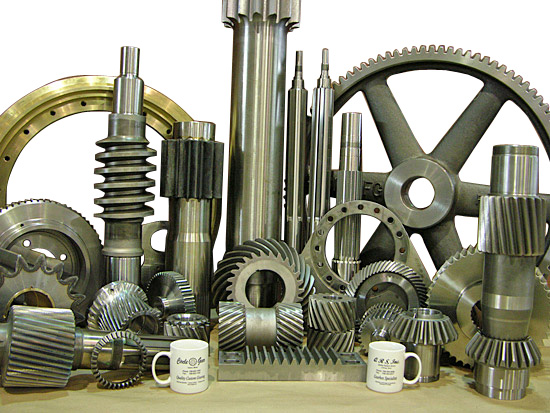

As a full service gear production shop, Circle Gear & Machine Co. features custom gear grinding services for all types of gears and finishing requirements, including roughing and machining. Our gear grinding machines can handle gears measuring up to 120″ in diameter, and types including bevel, helical, herringbone, internal, and worm gears. We can grind both gears and hobs, working to ISO standards.

We specialize in gear grinding processes such as precision grinding, regrinding, form grinding, and fine grinding, with CNC capabilities for maximum speed and efficiency. We will gladly accept grinding jobs in short or long runs, including specialty projects, and feature full inspection and quality control, with reports available.

Custom Gear Grinding Services Specification Table

| Industry Focus | Agricultural Auto/Truck/Transportation Machine Tool | Marine Medical |

| Intended Application | Gearing Machinery | Tooling/Fixtures |

| Industry Standards | ISO International Organization for Standardization |

|

| Part Types | Gears Hobs |

|

| Gear Types | Helical Planetary Rack and Pinion Splines Sprockets Spur Worm |

|

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run | High Volume Large Run Long Run Large Scale Production Volume Run |

| Process | Fine Grinding Form Grinding High Speed Grinding | Polishing Precision Grinding Regrinding |

| Automation Capabilities | CNC | |

| Quality Control Inspections | Standard Metrology Instruments Optical Profilometer |

|

| Additional Services | CAD Design Q.C. Reports | Reverse Engineering |