Our Herringbone Gear Capabilities

- Diameter: Max 60 inch

- Face Width: Max 18 inch

- Diametral Pitch: Min 16 DP Max 2 DP

- Gear Finishing Methods: Conventional Cut, Lapping For Double Helicals, see the Spurs/Helicals page

Herringbone Gears

Circle Gear & Machine Co. has been a trusted manufacturer of herringbone gears since purchasing our first herringbone machines in 1994.

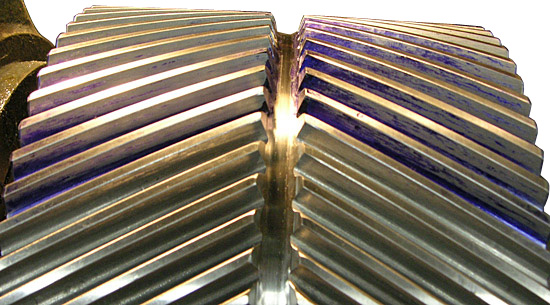

What is a Herringbone Gear?

Herringbone gears are a type of double helical gear that features a unique tooth structure consisting of adjoining, opposite helixes that appear to create a V shape. Unlike helical gears, they do not create an axial load. However, similarly to helical gears, they transfer power smoothly because more than two teeth are enmeshed at once.

How Do Herringbone Gears Work?

The smooth, precisely manufactured V-shaped teeth on herringbone gears mate them together. Since multiple teeth are engaged in the rotation process, the workload is more evenly distributed, offering quiet operation. Due to the reciprocal arrangement of the helixes, each side creates an opposing axial force that cancels the other out, preventing axial thrusts. There are two ways to manufacture the gear set’s teeth: so that one tooth-tip aligns with the opposite tooth-tip, or so that one tooth-tip aligns with the tooth trough on the opposite gear.

Herringbone Gear Applications

Since herringbone gears have a complicated production process and are challenging to cut, their use is limited to special applications, such as in large transmissions. Some of the most common herringbone gear applications include:

- Heavy machinery

- Torque gearboxes

- Heavy-duty vehicles

- Gas turbines

- The transmission of high torque

Additionally, the herringbone gear was a key step in the introduction of steam turbines to marine propulsion.

Herringbone Gear Advantages

The herringbone gear’s unique design creates numerous advantages. For example, they combine the high load capacity of helical gears with the lack of axial forces seen in spur gears. Herringbone gears also deliver smooth power transfer, since multiple teeth are enmeshed together at once. Their relatively long tooth length allows them to transmit high torques due to the inclination the design creates. Additionally, the side thrust of one half is balanced by the opposing half, allowing them to be used in torque gearboxes without needing a substantial thrust bearing.

Herringbone Gear Capablities

Circle Gear & Machine Co. offers extensive herringbone gear manufacturing capabilities and is prepared to meet your production demands with whatever your application requires:

- Diameter: Max 60 inches

- Diametrical pitch: Min 16 DP, Max 2 DP

- Module: 20

- Face width: Max 18 inches

- General capabilities: As needed, production, contract, just-in-time, small parts

- Primary capabilities: Die forming, heat treating, machining, finishing

- Materials: Acetal/Delrin, aluminum, alloy steel, bronze, brass, carbon steel, gray cast iron, ductile iron, plastic, nylon, phenolic, polyester, polycarbonate, stainless steel

- Industry focus: Automotive, biotechnology, chemical, construction, electrical, electronics, food processing, HVAC, machinery, marine, medical, mining, nuclear, oil, gas, petroleum, optical, packaging, pharmaceutical, plumbing, pneumatics, pulp & paper, pumps, semiconductor

- Shaft feature: Flat, hex

- Gear cutting methods: Broaching, climb hobbing, conventional hobbing, flame cutting, milling, shaping

- Gear forming methods: Centrifugal casting, die casting, forging, sand casting

- Gear finishing methods: Conventional cut, lapping

- Heat treatment methods: Carburizing, flame, induction, nitriding

- Production volume: Specialty production shop, prototype, low volume, small run, high volume, large run, long run, large scale production volume

Contact Circle Gear & Machine Co.

Herringbone gears offer efficient, high-capacity power transmission and are particularly useful in demanding heavy-duty applications. At Circle Gear & Machine Co., our skilled team crafts quality herringbone gears, including Sykes-cut herringbone gears, from our 46,000 sq. ft. manufacturing facility. Upon completion, all of our products undergo rigorous quality control testing in compliance with ISO 9001:2008. To learn more about our herringbone gear production capabilities, contact us today. To get started on your next project, request a quote.

Custom Herringbone Gears Capabilities

| Diameter | Max 60 Inch |

|

| Diametrical Pitch | Min 16 DP | Max 2 DP |

| Module | 20 | |

| Face Width | Max 18 Inch |

|

| General Capabilities | As Needed Contract Just-In-Time | Production Small Parts |

| Primary Capabilities | Die Forming Finishing | Heat Treating Machining |

| Materials | Acetal/Delrin Alloy Steel Aluminum Brass Bronze Carbon Steel Ductile Iron | Gray Cast Iron Nylon Plastic Phenolic Polycarbonate Polyester Stainless Steel |

| Industry Focus | Automotive Biotechnology Chemical Construction Electrical Electronics Food Processing HVAC Heating, Ventilation, and Air Conditioning Machinery Marine | Medical Mining Nuclear Oil, Gas, Petroleum Optical Packaging Pharmaceutical Plumbing Pneumatics Pulp & Paper Pumps Semiconductor |

| Shaft Feature | Flat Hex |

|

| Gear Cutting Method | Broaching Climb Hobbing Conventional Hobbing Flame Cutting | Milling Shaping |

| Gear Forming Method | Centrifugal Casting Die Casting Forging Sand Casting |

|

| Gear Finishing Methods | Lapping Shaving |

|

| Heat Treatment Methods | Carburizing Flame | Induction Nitriding |

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run | High Volume Large Run Long Run Large Scale Production Volume Run |