Additional Gearing

Worm and Worm Gears Sets

Our Worm and Worm Gear Capabilities

- Gear Diameter: Max 120”

- Worm Diameter: Max 10”

- Diametral Pitch: Max 1.5 DP / 20 Mod

CIrcle Gear proudly offers worm and gear cutting services. Our sales and engineering team will work with you to determine gear pitch and set center distance from your samples. With a large inventory of cutting tools, we can easily find a match for your project. We hand-roll test the worm set to ensure center distance, backlash, and pattern are within requirements. Worms are usually tooth ground to provide the smoothest action possible.

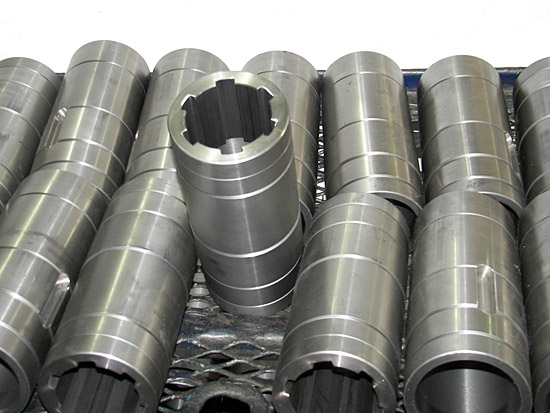

Spline Shafts

Our Spline Shaft Capabilities

- Shaft Diameter: Max 42” swing

- Shaft Length: Max 140”

- Pitch: Max 2.5 DP

As one of the top manufacturers of spline shafts, Circle Gear provides a wide range of configurations for our custom spline shafts. We work closely with our customers to ensure they get tailored spline shafts that meet even the most complex and unusual specifications.

At Circle Gear & Machine Company, we have served the gear market for over 70 years. With our experience machining spline shafts and other spline machining capabilities, we can assist you in finding the right size, shape, and tooth count for your specific application. Request a quote for our services today.

Additional Gearing

As a full-service provider of gear manufacturing services, Circle Gear features full machining capabilities for all types of gears. Our sales and engineering team can help you with non-standard pitches or modified designs due to ratio changes or gear box modifications. Please inquire if you have any questions for that following gear types:

- Straight / Spiral Bevels

- Helical Gears ( double helicals)

- Spur Gears

- Racks (Flat or cylindrical)

- Involute Splines

- Straight Sided Splines

- Worm and Worm Gear

- Herringbone Gears

- Timing Gears

- Sprocket and Silent Chain

- Planetary Systems

Gear Manufacturing Methods

We have the versatility to support almost every gear manufacturing method possible. We continue to upgrade our machines and capabilities to provide the most economical way to achieve the highest quality possible. Our current methods include:

- Hobbing (conventional tool steel with job specific coatings)

- Shaper Cutting (conventional tool steel with job specific coatings)

- Form Cutting

- Form Grinding

- Broaching

- Shaving

- Lapping

Manufacturing Support

With over 135 available listed manufacturing operations and 122,000 sq. ft. floor space dedicated to production, we can provide a solution to every feature of your part.

- Barstock sawing (16” Dia)

- Manual Turn & Mill

- CNC Turn & Mill

- O.D. & I.D. Grind

- Bore Hone

- Surface Grind

- Keys

- Deburring (manual and automatic)

- Stamping (Laser etch and dot peen)

- Magnetic Particle Inspection

- CMM Inspections

- Gear Metrology Reports

Materials and Heat Treating

Circle Gear has an impressive stock of raw materials and is acquainted with every type of material known to be used in the industry. Our sales and engineering team will work with you to decide the best materials when reproducing from samples and find the exact match from print. Please call to discuss any questions you have for materials and heat treatment processes that are available.

Materials:

Alloy Steels- 4140, 4340, 4320, 8620, 9310, 18CrNiMo7-6, 42CrMo4

Carbon Steels- A36, 1018, 1045, 1144

Aluminum

Stainless Steel

Tool Steel

Ductile Iron / Cast Irons

Bronze / Brass

Heat Treat Methods:

Quench & Temper

Carburize

Nitride

Flame Harden

Induction Harden

Die-Quenching

Industries that Utilize Our Gearing

To illustrate the versatility and reliability of various gear types, here are the main industries that use every type of gear we make.

- Automotive

- Biotechnology

- Chemical

- Construction

- Electrical

- Electronics

- Food Processing

- HVAC

- Machinery

- Marine

- Medical

- Mining

- Nuclear

- Oil, Gas, Petroleum

- Optical

- Packaging

- Pharmaceutical

- Plumbing

- Pneumatics

- Pulp & Paper

- Pump

- Semiconductor

At Circle Gear & Machine Company, we have served the gear market for over 70 years. With our experience manufacturing high quality gears with extensive machining capabilities, we can assist you in finding the best economical methods with the highest quality for your specific application. Request a quote for our services today.

Custom Involute Splines and Straight Sided Splines Capabilities

| Internal Spline | Max 42 Inch |

|

| External Spline | Max 120 Inch |

|

| Shaft Length | Max 140 Inch |

|

| Diametrical Pitch | Max 2.5 DP |

|

| Module | 10 |

|

| General Capabilities | As Needed Contract Just-In-Time | Production Small Parts |

| Primary Capabilities | Die Forming Finishing | Heat Treating Machining |

| Materials | Acetal/Delrin Alloy Steel Aluminum Brass Bronze Carbon Steel Ductile Iron | Gray Cast Iron Nylon Plastic Phenolic Polycarbonate Polyester Stainless Steel |

| Industry Focus | Automotive Biotechnology Chemical Construction Electrical Electronics Food Processing HVAC Heating, Ventilation, and Air Conditioning Machinery Marine | Medical Mining Nuclear Oil, Gas, Petroleum Optical Packaging Pharmaceutical Plumbing Pneumatics Pulp & Paper Pumps Semiconductor |

| Shaft Feature | Flat Hex |

|

| Gear Cutting Method | Broaching Climb Hobbing Conventional Hobbing | Milling Shaping |

| Gear Forming Method | Centrifugal Casting Die Casting Forging |

|

| Gear Finishing Methods | Grinding Honing | Lapping Shaving |

| Heat Treatment Methods | Carburizing Flame | Induction Nitriding |

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run | High Volume Large Run Long Run Large Scale Production Volume Run |